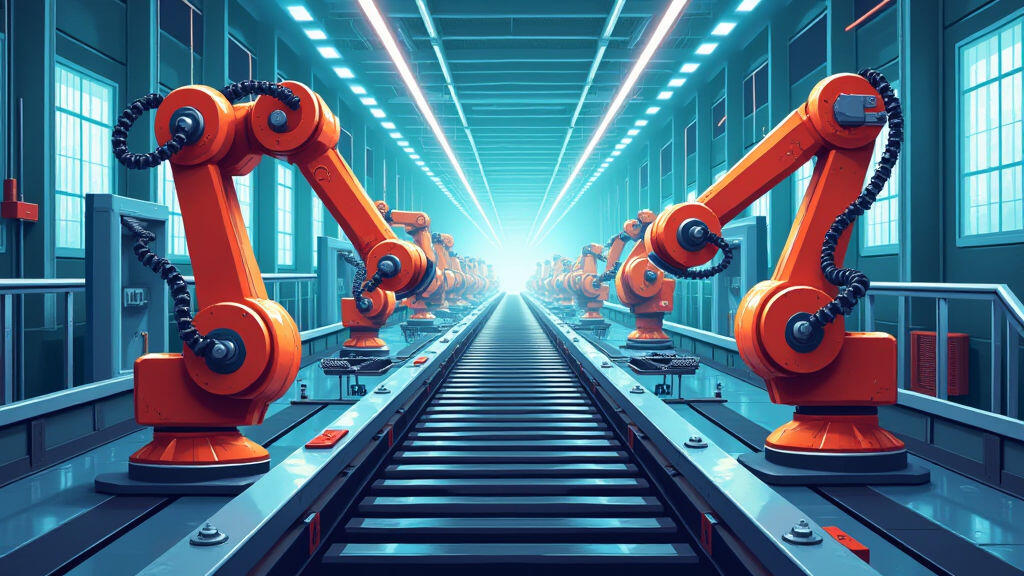

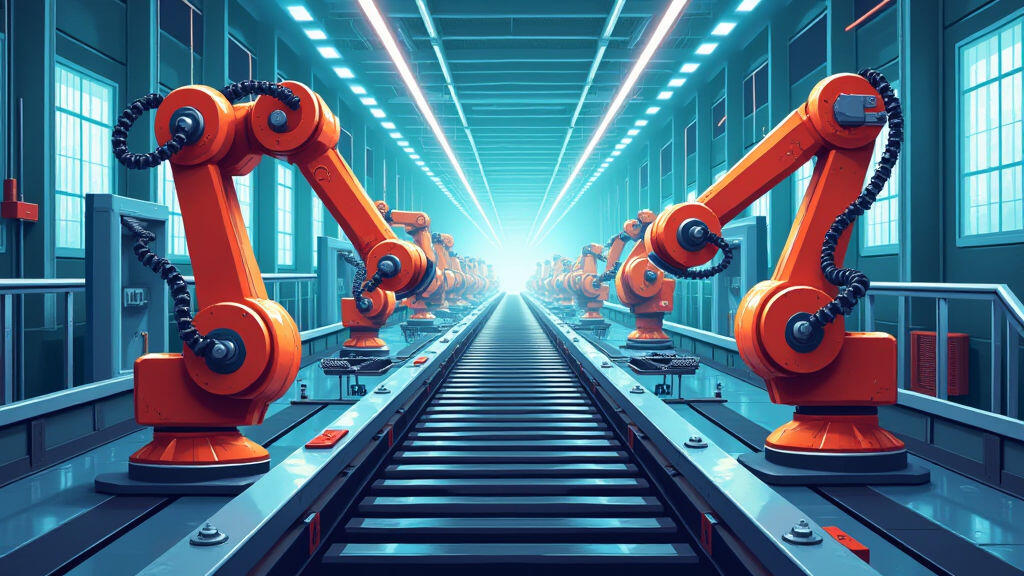

Modern supply chains have become the arteries of the global economy, transporting goods from raw material farms to bustling marketplaces in minutes that were unimaginable a few decades ago. At the heart of these logistics engines lies a deceptively simple mechanism: the gear motor. While often operated behind the scenes in conveyor belts, elevator hoists, and automated storage systems, the principles governing gear motors dictate performance, safety, and efficiency across the entire supply chain.

A gear motor is essentially a motor coupled with a gear train—a set of interlocking teeth that transform the motor’s high-speed, low-torque output into the low-speed, high-torque motion required by heavy-duty equipment. In conveyor belts that stretch for miles, the motor must deliver continuous force without overheating. In warehouse robotics, precise torque control allows robots to lift, sort, and transport fragile items without damage.

Think of a gear motor like a drummer’s metronome: the motor’s rhythm is fast and steady, while the gears pace the beat to match the workload’s tempo. This symbiotic relationship ensures that a logistics system can maintain speed without sacrificing strength, making gear motors indispensable for high-capacity transporting lines, automated palletizers, and high-speed pick‑and‑place machines.

1. Energy Efficiency

Gear motors reduce the load on the primary motor by stepping down speed and increasing torque. This lowers electrical consumption, which is critical for factories that operate 24/7. Energy savings translate into lower utility bills and a smaller environmental footprint—an increasingly important selling point for enterprises governed by sustainability mandates.

2. Durability and Reliability

Because the gear train absorbs strain, gear motors can endure prolonged heavy-duty use without frequent breakdowns. In logistics centers where uptime is paramount, fewer service interruptions mean higher throughput and less costly downtime.

3. Precision Control

Modern gear motors integrate electronic speed controllers (ESCs) and servo drives. These allow an operator to set exact speed profiles, smooth acceleration curves, and maintain consistent torque even when the load fluctuates. For instance, during pallet stacking, the motor can adjust torque to accommodate varying pallet weights, preventing both wheel spin and motor over‑stress.

4. Compact Design

Compared to hydraulic or pneumatic systems, gear motors are smaller and lighter, which is vital in confined warehouse spaces. A small motor can be positioned near the conveyor to reduce cable runs and simplify maintenance.

Consider a fulfillment center servicing a mega‑retail corporate. The plant uses a network of automated conveyor belts to transport items from sorting stations to shipping bays. Each belt runs on a gear motor array that can deliver up to 4,000 N of pulling force while maintaining a uniform speed of 1.2 m/s. By integrating a variable‑frequency drive (VFD), the center can shift the belt speed by ±20% during peak hours, ensuring that package flow matches shipment times.

Additionally, robotic pickers deployed along the belt use gear motors with integrated servo feedback to maneuver arms with millimeter precision. When a fragile glass item passes by, the motor slows the arm’s movement to 15 mm/s, preventing abrupt motions that could cause breakage. The combined gear‑motor system thus demonstrates the triad of capacity, precision, and safety that modern logistics demand.

Technology is pushing gear motors beyond basic time‑speed work. Advances in sensor technology now allow real‑time monitoring of temperature, vibration, and torque. These data streams feed into digital twin models—virtual replicas of the physical gear motor system. Engineers can run simulations to predict wear, detect malfunctioning gear teeth early, and plan proactive maintenance. This proactive approach reduces unscheduled downtime—an increasingly valuable competitive advantage.

Furthermore, the integration of mechatronic design has produced lightweight series‑gear motors that can spin up to 10,000 rpm while delivering high torque. Such motors are being adopted in micro‑factories where speed and exact positioning are lucrative for small‑batch production lines.

In the dynamic realms of logistics and conveying, gear motors serve as silent but crucial workhorses. Their ability to convert electrical power into precise mechanical work—while compensating for load variations and operating with high reliability—makes them a cornerstone of modern supply chains. As eCommerce demands continue to rise, and sustainability targets sharpen, gear motors will evolve further through smarter control systems, predictive analytics, and embedded sensors. By embracing these advancements, logistics operators can unlock new levels of efficiency, reduce maintenance costs, and ultimately deliver products faster and with less environmental impact than ever before.

Leave A Reply

Your email address will not be published. Required fiels are marked